Trailer Brake Troubleshooting | Fix Common Brake Problems

Table of Contents

Understanding Trailer Brake Systems

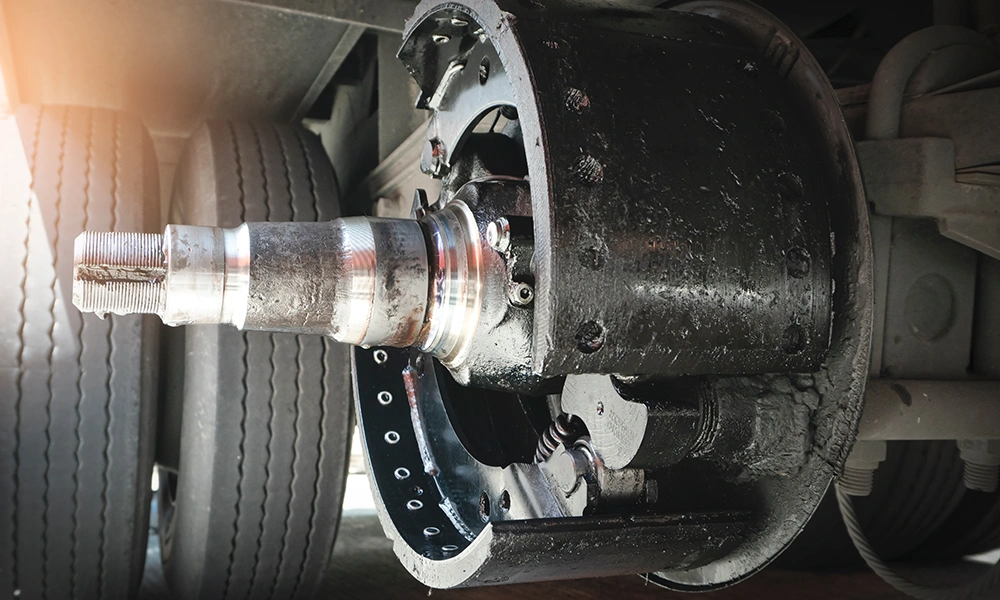

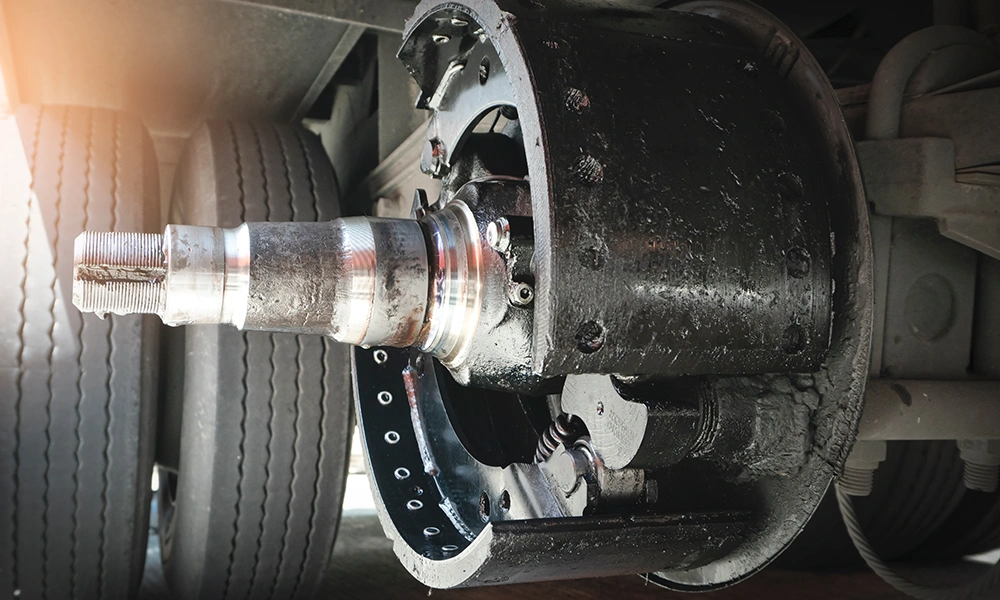

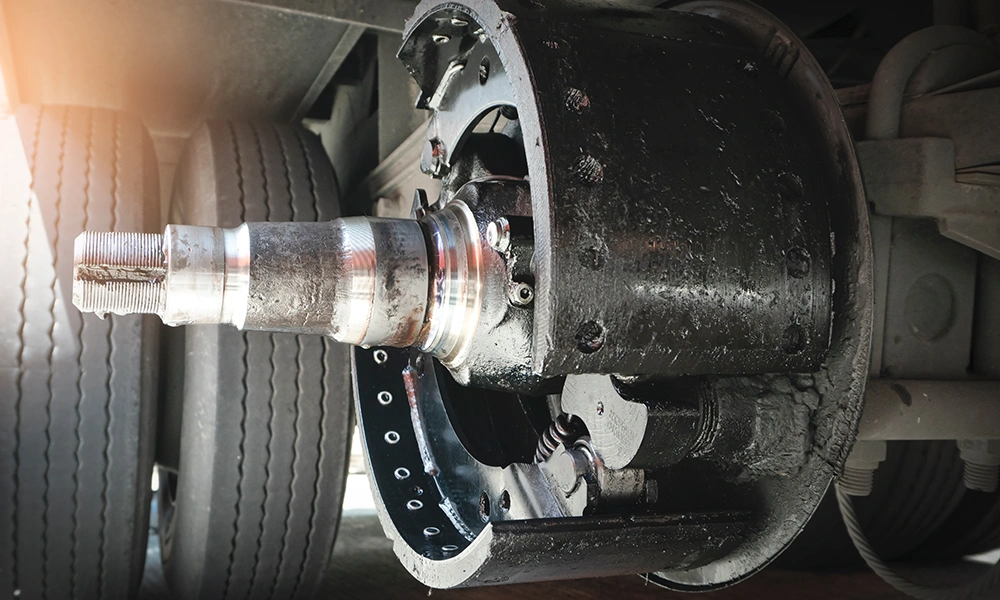

Before getting into the details of Trailer Brake Troubleshooting, it’s only appropriate to understand how these systems work. Trailer brakes are electrically precise; each component works like a chain reaction. The brake controller, wiring, magnets, drums, and lights must all be in sync in order to stop safely. It is stated by the National Highway Traffic Safety Administration (NHTSA, 2024) that most of the effectiveness of trailer braking is dependent on clean electrical signaling and the proper calibration of the controllers. When one of those links in that system is broken, the braking force is quickly lost.

When you press the brakes of your tow vehicle. The brake sends voltage to the brake magnets mounted on each brake assembly. Those magnets draw the brake shoes towards the drums to make friction. And it slows the truck down. However, this whole process is distorted over time. Corrosion, moisture, or loose connectors can become the major reasons for the electric trailer brake controller not working. And the best you can do is, inspect them before starting your journey.

Signs You Need Trailer Brake Troubleshooting

Most of the drivers become aware of the trailer brake problems when it is already too late. Either your trailer starts pushing too hard on the descent, or it simply doesn’t stop. But the fact is, your brakes will give signals way before they give up. Half of the roadside trailer violations associated with brakes can be prevented if the warning signs are detected during the pre-trip inspections. Not only is it time-saving, but being that attentive also saves you from the expensive roadside repairs.

Some of the symptoms that are common enough to warrant electric brake troubleshooting include slow braking response, uneven stops, dashboard brake warning, or your brake light on trailer not working. It’s not even the brake sometimes, it is wiring, the magnets, or even the corrosion in the connectors, interrupting the current. Disregarding these indicators is playing chicken with your own load weight. This is definitely not a wise nor a safe thing to do.

This guide will assist you in detecting the clues before your trailer turns into a roadside tale.

Breaks Not Engaging or Responding Slowly

One of the major trailer brake problems is that it starts taking more time to stop due to issues. It is usually a weak signal from the controller or poor ground wiring. OEM / NHTSA service bulletin (GM, 2024) recommends cleaning/inspecting trailer connector wiring and grounds. They cite poor connector condition as a cause of trailer electrical faults. Corrosion, loose connectors, and faulty brake magnets can really disturb the current flow. Use a multimeter to measure the voltage output at the brake magnets. 10.5 to 12 volts under load is ideal. Anything else? That’s a red flag that your controller or wiring is to blame.

Trailer Brakes Locking or Jerking

Locking or jerky braking normally indicates uneven distribution of voltages or eroded magnets, which pull more on one side. It may also occur in case the brake controller is over-calibrated. The most frequent issue with electric trailer brake controller trousbleshooting is brake lockups. They are typically associated with the magnet wear or defective controllers. It can be confirmed with the help of a simple resistance test using an ohmmeter. Too high or too low resistance means a change of magnets is needed.

Brake Lights / Tail Lights on Trailer not working

When tail lights on your trailer are out, that is not just a visibility issue; it is a safety violation. Among the five leading out-of-service reasons in the FMCSA Brake Safety Report, faulty lighting connections are included. You should start by cleaning the plug connectors, examining the pin corrosion, and testing the ground wire. That solves the problem nine out of ten times. Otherwise, go to the fuse box of your vehicle. Even the most basic repairs get ignored occasionally.

Trailer Feels Unstable During Braking

Common Trailer Brake Problems and their Fixes

When your trailer brakes are acting up, it is often simple yet sneaky. Most of the failures of trailer brakes are not caused by the malfunctioning of the brake part itself, but rather by the electrical failure. It is better to have some tests first before you start changing everything.

Faulty Brake Controller

The controller’s role is the same as that of a brain. Unless it transmits the correct amount of power, the brakes will not be effective. Most of the brake controller failures were due to improper calibration or a corroded connector, rather than the unit.

- Test the blue output wire using a multimeter – the voltage must increase steadily when you press the pedal.

- The controller may be faulty in case the voltage jumps or remains flat.

- Clean the trailer plug connectors and the ground wire – corrosion usually messes up the signals.

Weak or No Power to Brakes

The power supply is the first suspect if the electric brakes not working on trailer.

- Check the 7-way trailer plug. Watch out for corrosion of the plug; check if it is greenish or has loose pins.

- Measure the voltage of your tow vehicle battery; less than 10 volts might lead to a decrease in braking power.

- Test the breakaway switch – in some cases, the pin could be loose and break the circuit.

- Replace any broken or damaged wire that is brittle, particularly around an axle or plug.

Wiring and Connector Issues

Wiring faults often mimic brake failure. Cracked, pinched, or exposed wires, especially near the axle, can be dangerous.

- Turn off and check the 7-way connector. Corroded or loose pins are the usual suspects.

- Check the blue brake wire test voltage; it must go up steadily when you press the pedal.

- Close all contacts and secure grounds on both trailer and tow vehicle – even slight rust or paint may interrupt the connection.

Worn Brake Magnets

Brake magnets do not wear out quickly, so the symptoms show up. Your trailer may be a little more pushy on your tow vehicle than normal.

- Take a magnet tester or ohmmeter. The healthy magnet has a reading of 3.0-3.5 ohms (as stated by Dexter Axle Technical Manual).

- If resistance is off, change the magnets in pairs (left and right).

- Check the grooved or burned modes of the magnet face. That’s an obvious replacement sign.

Bad Ground or Corrosion

Even new brakes can behave like dead brakes when they are on poor ground.

- Wipe off the ground points on the trailer frame and tow vehicle.

- Check between ground surfaces if there’s any rust, accumulated paint, or grease.

Electric Trailer Brake Troubleshooting Steps

1. Inspect the Electric Connections

Begin by checking any electrical connection between the tow vehicle and the trailer. Check on loose, ripped, or corroded wires. Particularly around the plug or frame. Wipe all contacts and ensure that every connection is tight and secure. The brake signal can be interrupted by a single weak wire.

2. Test the Brake Controller

Ensure that the brake controller is operable. The majority of the models are equipped with a manual override lever or button to test the brake functionality without the pedal. If the brakes start responding weakly or don’t engage at all, look for the output voltage of the controller using a multimeter.

3. Inspect Brake Components

Test the brake shoes, the magnets, and the drums for wear, grooving, or any burns. Any part that appears scored or uneven should be replaced. Most trailer kits come with spare parts to replace most wear parts; thus, having spare parts will save you on the road.

4. Adjust Brake Shoes

Poorly fitted shoes reduce braking performance and lead to uneven wear. Use the instructions of your trailer manufacturer to set the correct clearance. A properly adjusted brake will drag a bit as you turn the wheel using your hand.

5. Check Wheel Bearings

Loose or failing bearings may result in uneven and unsafe braking. Jack up the wheel and rock it side to side. Any play means it’s time for inspections. Be aware of grinding/squealing. These are the initial indications that the bearings require servicing or replacing.

Trailer Break Light Issues

Brake light issues are not something new. It might also lead to serious problems when neglected.

- Inspect the trailer plug and connector: Check if there is any corrosion, bent pins, or loose fittings.

- Check bulbs and sockets: Change burnt out bulbs and clean dirty/oxidized sockets.

- Check and screw up ground points: Poor ground is a frequent cause of flickering lights or the brake light on trailer not working.

- Test circuits with a multimeter: Make sure power is going through the brake light wire when the pedal is released.

- Check all lights before you drive: To remain safe and compliant, check the brake, tail, and turn lights. Make sure they are functional.

Preventive Maintenance Tips

Preventive maintenance will help to prolong the service of brakes and will guarantee safe and legal trips. These are some of the rapid examinations that you should add to your routine:

- Conduct physical checks prior to each journey. Check broken wires, loose plugs, or deteriorated brake elements.

- Apply dielectric grease and clean connectors. It is to ensure solid electrical contact and to prevent corrosion.

- Check the brake calibration monthly. Check the correct braking force and response time.

- Replace worn parts as they wear out: Do not wait until they fail; replace magnets, shoes, or bearings.

- Check brake lights and signals. It is important to make sure that all lights are in working condition.

Frequently Asked Questions

There shouldn’t be any pulling or jerking when you slow the trailer. Brake response can also be tested with the manual override on your controller.

It is normally caused by the wiring corrosion, faulty ground, or a failed brake controller connection that interrupts the signal.

The most common reasons for bad or no braking power include corroded connectors or weak wiring.

Sure, some simple tests, such as wiring, connectors, and magnets, can be done with a multimeter and some cleaning equipment.

Yes, CS Truck & Trailer offers quality diagnostics, repairs, and replacements to maintain the safety and compliance of your trailer.

Recent Posts

Author

Margaret Johnson

Fleet Industry Copywriter – CSTT

Margaret Johnson is a professional content writer specializing in fleet management, vehicle maintenance, and repair industry insights. I create well-researched, practical, and SEO-driven content that helps fleet managers and business owners make informed decisions. With a focus on clarity and value, Margaret translates complex technical topics into easy-to-understand, actionable information.