Fleet Maintenance Schedule: Reducing Downtime and Repair Costs

Is your fleet always chasing repairs instead of preventing them? This guide is for you! Keeping trucks safe, compliant, and profitable will become easier than ever.

“We are what we repeatedly do. Excellence, then, is not an act, but a habit.” — Will Durant.

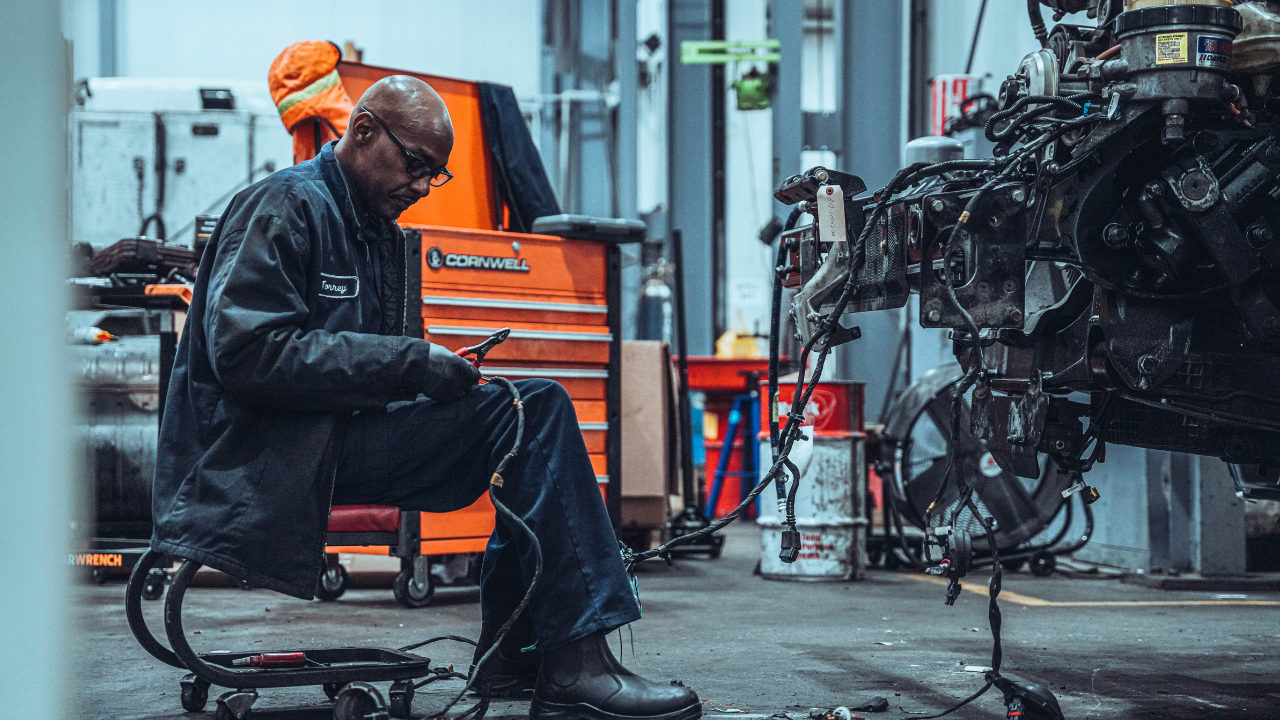

An occasional inspection will not make your fleet profitable but consistent, scheduled maintenance will. Steady and disciplined maintenance is necessary to keep your fleet reliable and compliant. Every oil change, inspection and system check contributes to a habit of reliability. Many fleet owners follow a maintenance routine religiously to build a culture of excellence, it saves a lot of money and reduces risks, keeping every vehicle performing at its best mile after mile.

“According to a 2023 Fleet Advantage study, nearly 60% of unplanned maintenance events stem from issues that could have been detected weeks earlier during routine inspections.”

The result? Delayed shipments, overtime costs, and driver frustration. Preventive maintenance is a strategic advantage, not a mechanical task. A structured fleet maintenance plan will keep your fleet earning instead of waiting in a service bay. Downtime can be reduced efficiently and emergency repairs will no longer be a problem for you.

Table of Contents

Components of a Fleet Maintenance Schedule

A fleet maintenance is a systematic approach to track service intervals, inspections and repairs across all vehicles in your fleet. Following a strict fleet maintenance schedule will enable you to manage a fleet of any size, but do remember, consistency is the key. Every vehicle has different service needs depending on mileage, load type and operating conditions. Having a clear truck maintenance plan keeps everyone accountable.

- Inspection Planning

- Maintenance Tracking

- Compliance Management

- Cost Control and Budgeting

- Telematics and Data Monitoring

- Scheduling and Coordination

- Reporting and Analytics

- Vendor and Parts Management

“According to a study, fleets that maintain regular inspection cycles reduce unexpected breakdowns by 32% and extend vehicle lifespan by up to 20%.”

With the help of a digital fleet maintenance sheet or management system, you can automate reminders. Also, it will help you record service logs and monitor component wear. Telematics and software tools have now become important components in fleet management to track odometer readings and send alerts for upcoming service. It will eliminate guesswork and dramatically reduce human errors.

Types of Preventive Fleet Maintenance Schedules

Depending on your fleet size, your preventive fleet vehicle maintenance schedule can be structured in different ways. Asset types and pattern usage should also be considered before selecting the type of preventive maintenance schedule. Many fleets combine time and meter-based scheduling. When these are paired with a proactive maintenance strategy, you can achieve excellence.

Meter-Based vs. Time-Based Scheduling

Time-based: A calendar will be the main component for scheduling service tasks (Example: every 30 days)

Meter-based: For meter-based scheduling, you’ll need odometer readings and engine hours. (e.g., every 3,000 miles or 150 hours)

Fleets that operate under different conditions should go for meter-based scheduling.

Creating a Fleet Preventive Maintenance Program

- Monitor the use of vehicle: Every small detail, including mileage, engine hours and driving conditions, should be recorded.

- Set Service Intervals: The vehicle should be aligned with manufacturer guidelines and fleet operating data.

- Document every repair: Maintain detailed records. It will become easy to spot recurring problems early.

- Standardizing Processes: Use a single preventive maintenance sheet or checklist for consistency.

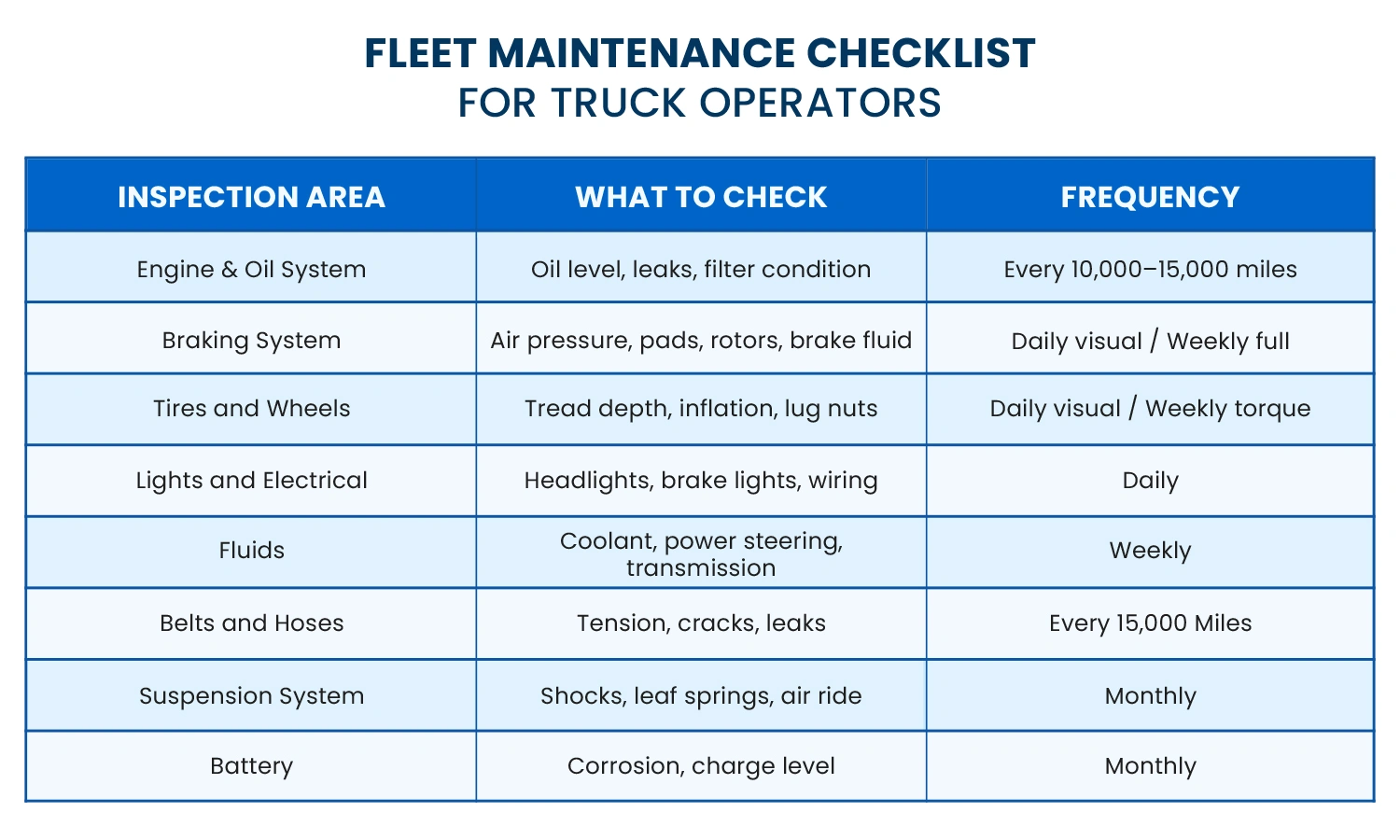

Fleet Maintenance Checklist for Truck Operators

A truck’s reliability matters the most when it hits the road. It’s important for operators to follow a structured fleet preventive maintenance checklist. A good checklist will ensure safety, performance and compliance areas. If you plan to reduce unplanned downtime and improve fuel efficiency, regular inspection will help you achieve that. Your vital components will also have an extended lifespan.

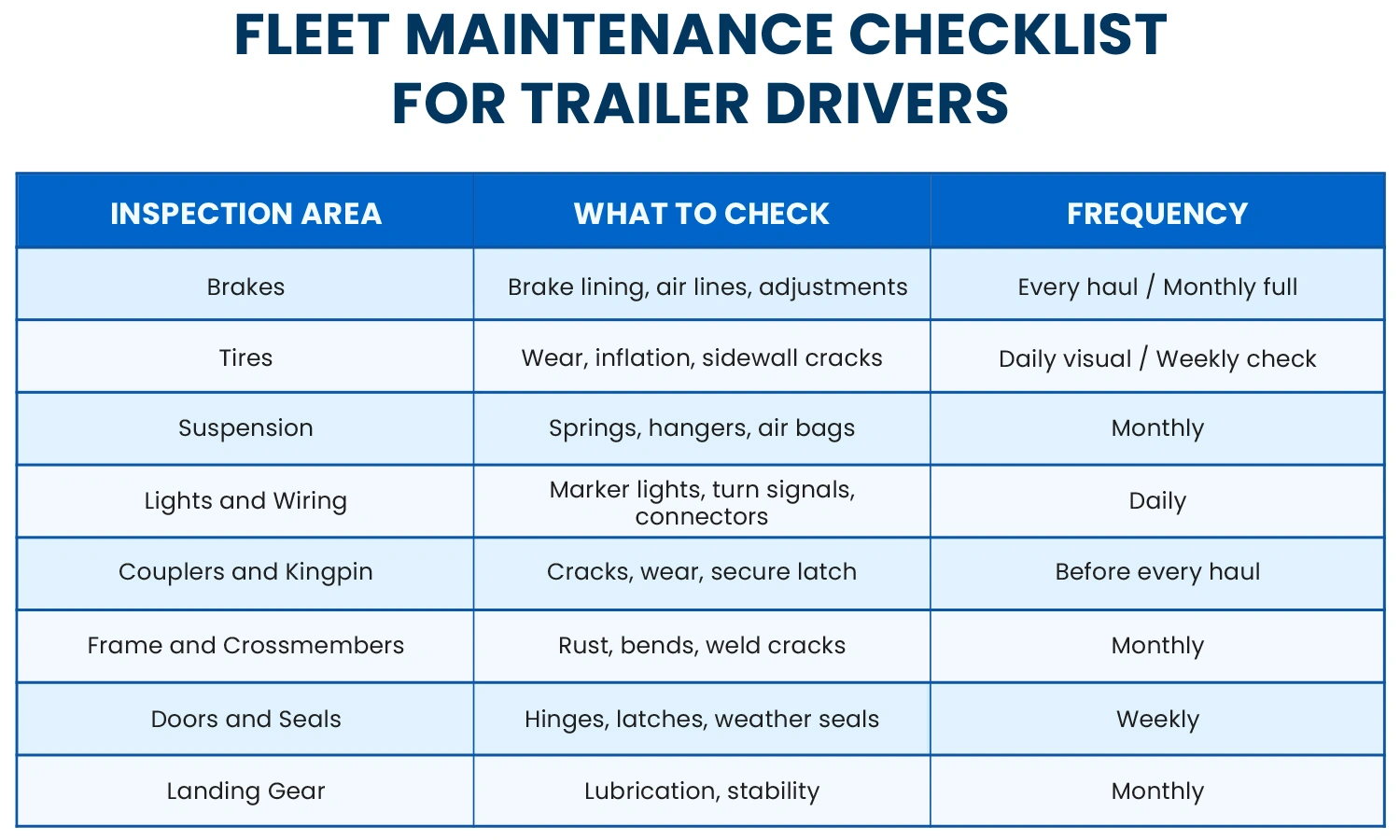

Fleet Maintenance Checklist for Trailer Drivers

Your trailers have to deal with constant stress from heavy loads and road shocks. But a detailed fleet maintenance schedule will help you prevent common trailer issues. Routine checks before and after every haul keep operations safe and DOT compliant.

Common Fleet Maintenance Mistakes to Avoid

No matter how experienced a fleet manager is, there’s always a possibility of making minor oversights. These small, neglected issues later turn into bigger breakdowns. Watch out for these common pitfalls:

- Oil leaks, tire wear, or vibration can easily go unnoticed. They are major components that can lead to costly failures.

- Skipping scheduled truck fleet maintenance inspections under pressure. This creates gaps in compliance and safety.

- Depending only on driver reports. You should always rely on documented checks or certified technician approvals.

Choosing the Right Commercial Vehicle Maintenance Program

Frequently Asked Questions

A fleet maintenance schedule has everything needed to keep your trucks on the road. It includes planned service intervals for inspections, oil changes, brake changes, tire rotation and component replacements. Preventive and predictive maintenance, both are scheduled based on mileage, engine hours and manufacturer recommendations. You’ll be able to identify wear and keep your trucks reliable and road-ready.

Depending on usage and conditions, fleet vehicles should be serviced after every 10,000 to 15,000 miles or at least every 3 months. If you have a heavy and long-haul truck, you may require more frequent checks, especially for brakes and fluids. A good fleet maintenance schedule will ensure consistent servicing. Your components will have a longer lifespan.

Reduced repair cost is the key advantage of a well-structured fleet preventive maintenance program. It comes with improved efficiency and reduced downtime.

You can create a fleet maintenance sheet by listing all vehicles, service intervals, and inspection tasks (oil, tires, brakes, filters, suspension, lights, etc.).

Note down dates, mileage, technician notes, and next due dates. Many fleets use spreadsheets or digital fleet software to automate reminders. It helps to track maintenance histories efficiently.

Preventive maintenance is important for commercial trucks to operate safely and efficiently. It prevents small issues from turning into huge ones.

Conclusion

Recent Posts

Author

Margaret Johnson

Fleet Industry Copywriter – CSTT

Margaret Johnson is a professional content writer specializing in fleet management, vehicle maintenance, and repair industry insights. I create well-researched, practical, and SEO-driven content that helps fleet managers and business owners make informed decisions. With a focus on clarity and value, Margaret translates complex technical topics into easy-to-understand, actionable information.