CDL Pre-Trip Inspection Checklist For Commercial Drivers

One of the most important things that every commercial driver must go through before starting a trip is a CDL Pre-Trip Inspection Checklist. It assists the drivers to stay compliant with DOT regulations, avoid roadside violations, and identify minor safety issues before they turn into major problems. Following an inspection routine will not only keep your license safe, but also your cargo, whether you are going to take your driver test or you are starting a long haul.

A pre-trip inspection checklist minimizes missing components that are overlooked during daily checks and ensures consistent inspection. The CDL pre-trip inspection list or a full CDL pre-trip inspection checklist is followed by the majority of drivers, whether they are preparing for a test or having real-world driving lessons.

To guarantee safety and the driver’s confidence on the road, many instructors focus on a CDL Class A pre-trip inspection checklist as part of the CDL driving test checklist during the training.

Table of Contents

Understanding CDL Pre-Trip Inspections

A CDL pre-trip inspection is a legally required safety process that confirms your commercial vehicle is roadworthy before operation. This inspection follows a standardized CDL inspection list, covering brakes, tires, lights, steering, and emergency equipment. Consistency is important for preventing violations and breakdowns, whether you’re using a CDL pre-trip checklist for daily driving or a CDL pre-trip inspection class A checklist for testing.

Different Pre-Trip Inspection Classes of CDL

The commercial driver license is divided into three major categories A, B and C. Each of them has inspection requirements.

CDL Class A Pre-Trip Inspection Checklist

- Covers tractor-trailers or combination vehicles that have a GCWR of greater than 26,001 lbs. And whose towing capacity exceeds 10,000 lbs.

- The areas of focus are coupling devices, trailer brakes, fifth wheel, suspension, and air lines.

- The systems of the tractor and those of the trailer should be inspected by the drivers during the CDL Class A pre-trip inspection.

- A CDL A pre trip inspection list or CDL pre trip inspection cheat sheet should be used to be reminded of all the connections points and brake checks when taking the CDL driving test checklist.

Class B CDL Pre-Trip Inspection Checklist.

- Applies to those vehicles over 26,001 lbs that are single such as box trucks or buses.

- Emphasis is made on air brakes, mirrors, lights, tires and passenger safety equipment.

- In Class B checks there are no checks on couplings but focus on interior safety and accessibility.

Class C CDL Pre-Trip Inspection Checklist.

- Covers less commercial vehicles that transport hazardous materials or 16+.passengers

- The areas of concern are the seat belts, mirrors, emergency exits and warning devices.

- Guarantees complete safety of passengers and cargo.

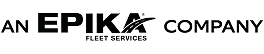

CDL Truck Inspection Checklist

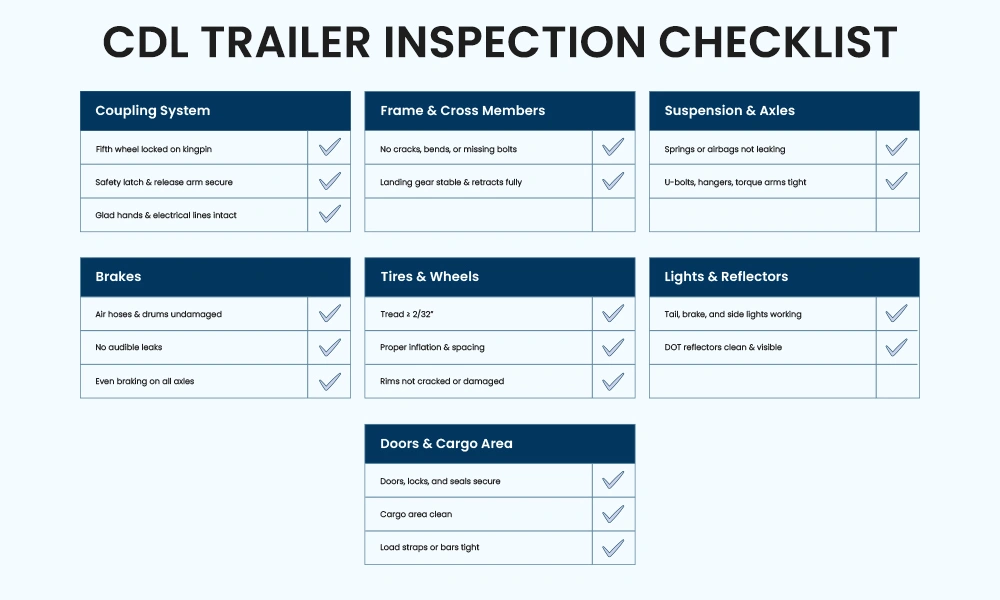

Trailer CDL Inspection

For combination vehicles, inspect the trailer as thoroughly as you check the tractor. Start at the point of coupling, with the glad hands sealed, the electric lines should be secured, and the fifth wheel locking jaws fully engage with the kingpin. The release arm and the safety latch are to be locked properly.

The frame of the trailer, the cross members, and the landing gear must be checked whether there are any cracks or bends, or they are any missing bolts. The suspension should bear airbags or leaf springs that are not leaking. Ensure that the rear doors are well latched and reflectors are neat. All the axles, tires, and brakes must be examined to be in even condition and have non-hazardous treads. The whole trailer should be inspected in order to avoid detachment or loss of control.

Important areas a CDL driver should check before starting a route are listed below.

Exterior CDL Inspection List

The exterior examination of the CDL driving test checklist starts with the visual inspection of the car by walking around it.

- Check truck tilt for suspension issues.

- Inspect underside for any fluid leaks.

- Ensure lights, reflectors clean and visible.

- Check mirrors, windshield, doors for cracks.

- Confirm tread depth: 4/32 and 2/32.

- Measure tire pressure with air gauge.

- Look for rust streaks on lug nuts.

- Ensure mud flaps, plates securely fastened.

If you’re looking for affordable truck body repair and painting, Contact CS Truck & trailer.

Engine Compartment Pre-Trip CDL Checklist

- Check hood condition for leaks or damage.

- Open hood and inspect components thoroughly.

- Ensure all fluids between MIN and MAX.

- Verify proper fill of all reservoirs.

- Belts and hoses clean without ABC damage.

- Belt play should be half-inch maximum.

- Inspect alternator, compressor, water pump securely.

- Ensure no leaks or frayed cables.

- Steering gearbox and pitman arm lubricated tightly.

CDL Pre-Trip In-Vehicle Inspection List

Check the safety and functionality of all the interior systems inside the vehicle. Pre trip CDL checklist is incomplete without an in-vehicle inspection.

Seatbelt must clasp, slide smoothly without frays.

- Turn ignition to verify indicator light functions.

- Check ABS, air, oil indicator lights.

- Ensure mirrors, wipers, defrosters provide visibility.

- Oil pressure should read 25–50 psi.

- Air pressure optimal between 120–140 psi.

- Voltmeter must stay between 13–14 volts.

- Temperature gauge should remain in normal range.

- Test city horn and air horn operation.

- Confirm all interior and exterior lights working.

- Fire extinguisher must be fully charged.

- Three reflectors present with spare fuses.

Brake System CDL Inspection List

The brake check is the most important safety measure. Inspect the air brake hoses for leaks, cuts, or audible air loss. There is a maximum of one inch of free play. It should never be exceeded. Make sure there is a 90-degree angle between the brake chamber and slack adjusters. The brake drums should be in the form of plain disks. Check for any cracks or heat discoloration. The linings are to be at least ¼-inch thick.

Conduct an air brake test with four parts as part of the SALE procedure:

- Static Test: Shouldn’t be more than 3 PSI loss in 60 seconds.

- Applied Pressure Test: No more than 4 PSI loss in 60 seconds under brake pressure.

- Low Air Warning: Buzzer/light activates around 55 PSI.

- Emergency Pop-Out: Valves release between 20–45 PSI.

How CS Truck & Trailer Helps Drivers Pass CDL Inspections

CS Truck & Trailer assists commercial drivers and fleet operators by making the whole process of CDL inspection easy and minimizing the chances of violations. Practical training and expert care maintenance give drivers confidence to complete a CDL pre-trip inspection checklist correctly and uniformly. With this preventative approach, small mechanical problems are addressed beforehand, avoiding expensive roadside breakdowns and unsuccessful DOT inspections.

Besides regular inspections, CS Truck & Trailer also has an organized inspection preparation to resemble actual DOT and CDL inspection conditions. Drivers are educated on how to follow a full CDL driving test checklist, essential safety elements, and accurately record inspections with DVIR standards.

With expert technicians, compliance-focused systems, and fleet-level support, CS Truck & Trailer ensures vehicles remain roadworthy while helping drivers pass inspections with confidence and efficiency.

Final Pre-Trip Checklist Before You Hit the Road

A last walk-through before commencing your route will make sure that you had not missed something in your previous inspections. The final review ensures safety, compliance, and readiness of drivers and ensures that all the components are operating well. A strict end-check minimizes the possibility of violations on the road and safeguards the driver and the cargo during the journey.

Check:

- Exterior Lights

- Tires

- Mirrors

- Leaking Fluids

- Check rake air pressure

- Dashboard warning lights

- Emergency equipment inside the truck.

The last step involves conducting a structured CDL truck inspection checklist to ensure that drivers do not break the DOT standards and stay consistent throughout their daily trucking operations.

It is advisable to add this routine to the regular practice, which will guarantee safer trips and easier road inspections.

Contact CS Truck & trailer for Complete CDL & DOT Compliance Services.

Frequently Asked Questions

A CDL pre-trip checklist is a complete guideline of all the parts of the vehicles. It means all the parts should be inspected by commercial drivers by the time they start their journey. It also makes sure that the trucks comply with the FMCSA and DOT safety standards on the road.

The drivers should make a CDL pre-trip inspection their daily habit. It keeps everyone safe if done prior to the use of a commercial vehicle. This inspection is also to be registered in a Driver’s Vehicle Inspection Report (DVIR).

The inspection focuses on the tractor and trailer systems. It includes brakes, coupling devices, suspension, tires, and lights. These areas cover all the major safety points that need to be checked.

Yes. Although examiners will not permit the use of a physical checklist during test, practicing with free CDL pre trip inspection checklist will help you in recalling the procedure as well as what to pay attention to during the test.

Absolutely, CS Truck & trailer offers complete CDL inspection compliance packages, such as digital DVIR setup, fleet maintenance tracking, and pre-inspection training for drivers and managers.

Schedule Your CDL Inspection Prep with CS Truck & trailer Today!

Recent Posts

Author

Margaret Johnson

Fleet Industry Copywriter – CSTT

Margaret Johnson is a professional content writer specializing in fleet management, vehicle maintenance, and repair industry insights. I create well-researched, practical, and SEO-driven content that helps fleet managers and business owners make informed decisions. With a focus on clarity and value, Margaret translates complex technical topics into easy-to-understand, actionable information.